Oklahoma Dredge Manufacturer Builds Quality Machines For Sludge, Sand and Gravel

Gene Maitlen considers VMI's cutterhead the most successful part of the company's dredge design. The cutterhead is so effective because it is a direct feed to the pump, says Maitlen, company president. As the cutter revolves, the pump sucks a full width draw into the recessed-impeller pump, without having to auger the material to the center. The cutter is reversible, so the dredge can move backward and dig with the same efficiency as when moving forward.

The company fabricates the patented horizontal cutterheads, including the teeth, along with portable dredges from four through 12 inches.

VMI (Vaughn-Maitlen Industries) operates from a new manufacturing complex in Cushing, OKlahoma, 65 miles northeast of Oklahoma City. In business since 1972, VMI's major customers have been sludge and industrial pond operators. When they moved into their new facility last year, they increased both capacity and capability, and are now turning out regular cutterhead dredges in pump sizes up to 12 inches, where previously their largest dredge was 10 inches. They have already sold one of these larger dredges to a sand and gravel producer in Wichita, Kansas, and have just completed another.

Maitlen's business partner is Bob Vaughn, with whom he spent a career selling construction equipment. Seeing a need for a portable dredge for sludge management, they started their dredge manufacturing company, producing a heavy, durable pontoon-mounted dredge that had immediate success in the industry.

Gene Maitlen has returned to Cushing, the home of his pioneer forebears, and lives on the ranch where he grew up. He enjoys the dredge business and works with wife Peggy and sons Tony and Randy. They made the move from Bethany, Oklahoma - a suburb of Oklahoma City - in March 1989, seeking a rural lifestyle as well as expanded manufacturing facilities.

Peggy is the secretary/treasurer of the company, and greets visitors from her desk in the main lobby. Randy, who started with the company at its outset, designs the dredges and modifications and is working on a totally computer-operated dredge. Tony joined the company in 1976 as sales manager. Of a more cosmopolitan bend, Tony enjoys traveling for the business for sales and customer support. International Sales Manager Henry Boschen calls on customers in the northeast United States as well as in other countries.

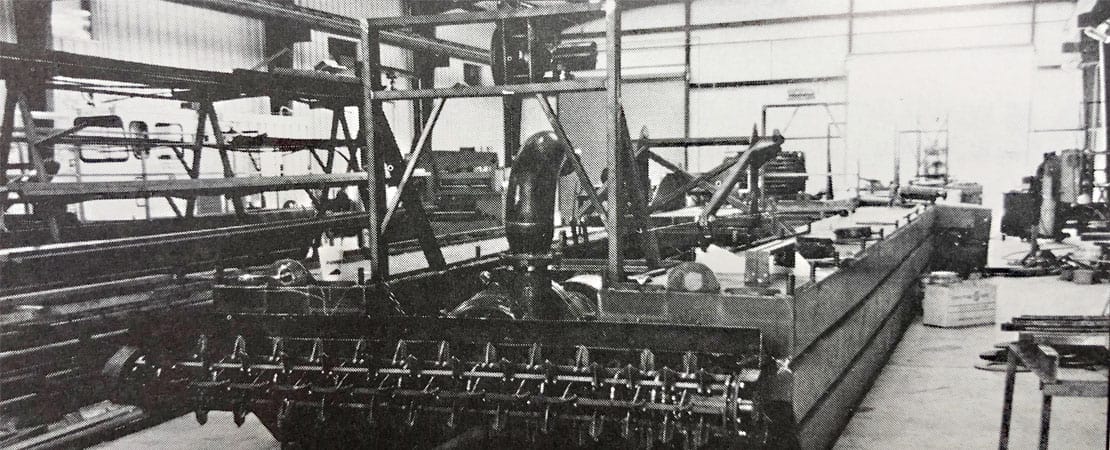

Maitlen designed the building with input from Peggy and his sons, and contracted the construction locally. The shop/office is a two-story corrugated steel building painted the company's signatory sky blue, with comfortable offices in front and the shop running the length of the building in back. An overhead crane serves the entire shop, where three or four dredges can be in progress at the same time. Fabrication facilities for the cutters and teeth are conveniently placed and one wall is dedicated to storage of spare parts.

Behind the shop a second building - a paintroom equipped with infrared heat lamps - holds a dredge newly painted sky blue. This is a 12 inch standard cutterhead dredge - one of the first non-horizontal cutters they have made. VMI dredges are coated with coal tar epoxy below the waterline after being sandblasted to bare metal. Anodes are added when a dredge is bound for seawater, to resist corrosion.

Over the years they have modified the dredge design to add certain improvements. A rubber shock absorber on the cutter motor takes the impact and prevents the drive shaft from breaking if the cutter hits a rock or other hard objects. All the systems are hydraulic, operated with each circuit having its own individual pump. This givies it the capability of all systems operating simultaneously without any loss of power. Using Cummins and Cat engines for power, VMI puts a 234 horsepower engine on a six inch dredge, correspondingly larger engines on larger pumps. This is more power than other manufacturers use, says Maitlen, but it insures that all the systems have adequate power at all times.

The cutter suction dredges operate from swing cables and spuds, while the horizontal cutter dredges move on a single line traverse anchored on shore. All functions are variable speed and not operated from gearboxes. Combined with adequate horsepower to drive the system, VMI's machines maintain sufficient head to move material as far as necessary in any project. Relief valves are built into the hydraulic pumps and motors.

The dredge pontoons are filled with foam to prevent the dredge from sinking. This is important in remote areas, where armed passersby may take pot shots at a dredge, says Maitlen. Even if someone drilled a line of holes with a machine gun, a foam-filled dredge would only float lower in the water, he said.

Since the move to Cushing, part of the identity of the company is taken from the town and surrounding territory, the traditional land of the Sac and Fox Indian nation. One of VMI's welders, Josh Williamson, is a full blooded Sac and Fox who does competition Native American dancing throughout the country in his spare time. Dressed in full regalia, he entertained at VMI's opening ceremonies last March when the facility opened, along with several other local dancers. Prisci Dean, another VMI employee, is also part Sac and Fox.

"I suppose your first quesion is why anyone is building dredges in the middle of Oklahoma," said Maitlen to a visitor. Besides giving the family a rural lifestyle in their ancestral home, Cushing offers a good opportunity for business. The local Chamber of Commerce offers land at no cost to new industry moving in, and donated six acres worth $3000 an acre to VMI in a business park east of town. VMI provides 15 jobs, an annual payroll exceeding $200,000 and county taxes.

Dependent on the oil industry, Cushing has seen a decline in recent years and has a workforce eager for employment, according to Tony Kaai, President of the Chamber of Commerce. A rural community of about 8000, Cushing is an old-fashioned prairie town, with clean wide streets lined with hundred-year-old houses. VMI's presence in the community has added jobs and income, and the Maitlens' valuable participation in the community. They give dredging a good name on the great plains.